Leading the way in food microbiology with innovative laboratory automation

in Innovation and Insights, Laboratory Testing

Author: AsureQuality

2323

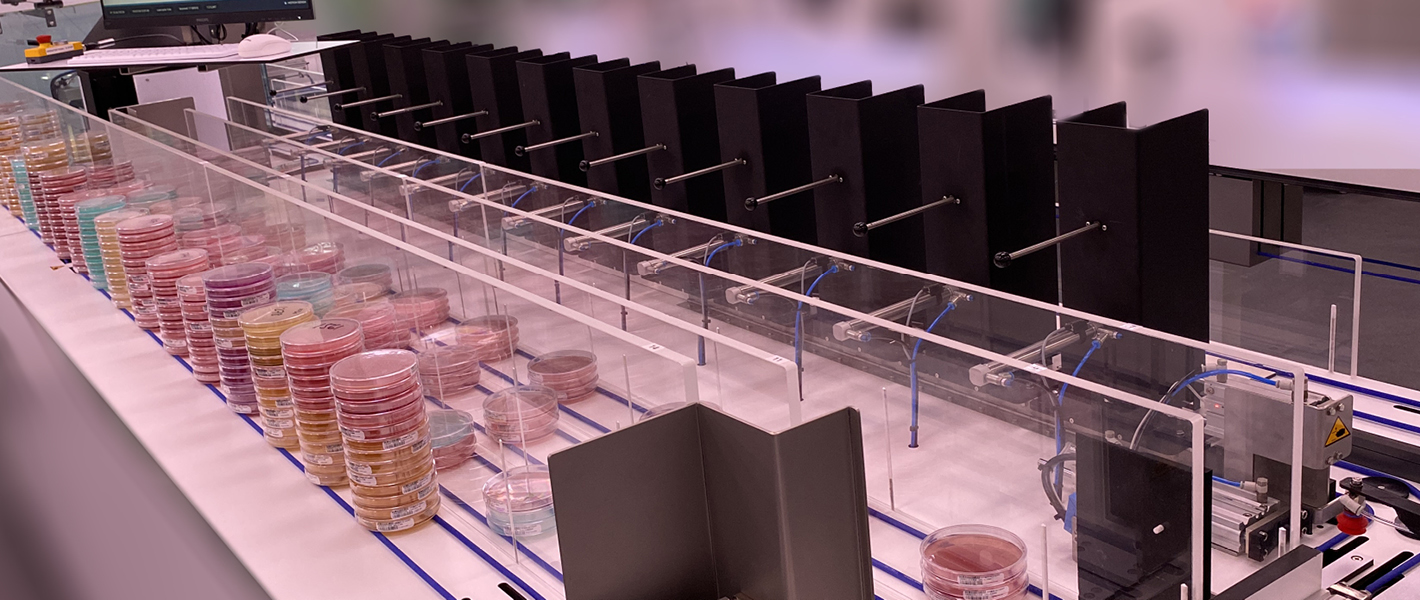

New digital plate interpretation technology coupled with advanced automation have been introduced in the microbiology department at AsureQuality’s Food Laboratory in Auckland.

The solution is the first of its type to be installed in a New Zealand food laboratory and is a key part of AsureQuality’s digitalisation strategy.

Microbiology testing is a critical part of food quality and safety control programmes. It allows food producers and manufacturers to identify bacteria or fungi related contamination and can also help to determine the quality and shelf life of products.

Microbiological analysis of food samples is performed by counting bacterial or fungal colonies growing in a petri-dish, which can be time-consuming and labour intensive as this is traditionally a manual process.

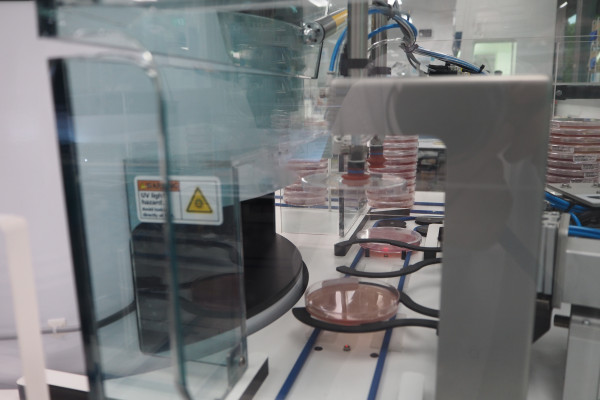

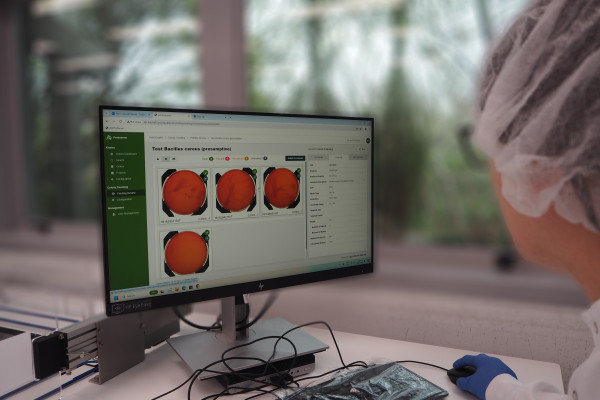

Now, the laboratory uses an automated imaging system with an ultra-high-definition camera and AI technology to assist with petri-dish interpretation.

AsureQuality partnered with Auckland-based technology company, Motion Design, to develop and build an end-to-end integrated system to fully automate the process of imaging, sorting and movement of petri-dishes through the post incubation processes. The project has been a pioneering collaboration between digital imaging, software, mechanical and food microbiology experts.

The laboratory’s technical manager, Warwick Aspin, says that the new technology will enable the laboratory to manage increasing demand, and brings about benefits for the microbiology team, laboratory customers and the environment.

“Our experts are still involved in reviewing and verifying the outcome of the AI analysis, but many of their manual and administrative tasks are now automated, allowing our people to focus on what they do best, which is the science.”

The removal of manual data entry into the laboratory information system (LIMS) and automation of result calculation eliminates the possibility of human error in these tasks. The customised review software manages the multitude of rules and conditions involved in microbiology interpretation required by various method references, and the integration of customer specifications allows quicker notification of out-of-specification results.

“In the past results would need to be calculated, then entered in our LIMS to confirm whether they met the customer specification. Now we can provide customers with an earlier warning of any out-of-spec results, allowing immediate action to be taken where required,” says Warwick.

Another key benefit is the ease of traceability, with all dishes now tracked and traced from the start to the end of the testing process, enabling the lab team to check the status of tests in progress at a glance. Images of plates processed via the automation are retained in a digital archive, and can be made available to customers as additional data to support investigations, if required.

The change will be good for the environment too – with the lab now able to adopt an improved paperless workflow. With automation driving the sorting of petri-dishes for disposal, clean plastics can more easily be separated. The new process is estimated to facilitate the recycling of approximately 17,000 kg of single use plastic each year, contributing to AsureQuality’s 2025 target to reduce weight of waste to landfill by 25%.